|

| June 07, 2016 | Volume 12 Issue 21 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

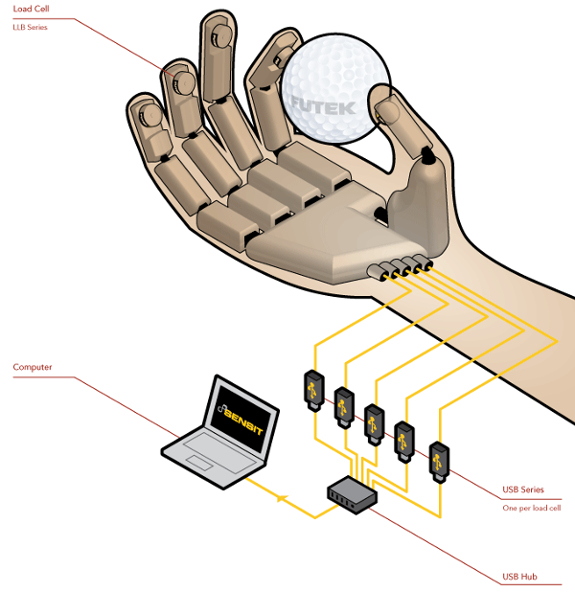

Application Note: Auditing robotic prosthetics

By FUTEK Engineering

They say to make an omelet you need to break a few eggs. Of course, it helps when the eggs are broken into the bowl, and not broken in the carton prior to taking them out.

With advancements in prosthetics allowing fine motor control driven by a patient's nervous systems, the use of miniature load cells placed at grip points helps observe a wide variety of operating conditions the patient requires from their prosthetic every day.

A load cell has to meet many requirements to be fit for use in a robotic prosthetic:

- A small footprint to fit within the 20-mm diameter of the average human fingertip;

- A wide range and high resolution to cover the average human fingertip momentary hold strength of 13 lb;

- Moving back to the omelet example, a low non-repeatability to ensure that all the eggs remain unbroken, and not just every other egg; and

- A wide operating temperature range so that even extremes like the cold of the Antarctic (-45 deg C) and the heat of Death Valley (55 deg C) do not inhibit function.

FUTEK mini load button LLB130.

FUTEK's miniature button load cells (LLB130) meet and exceed the requirements for sensors in robotic prosthetics. The sensors are 9.5 mm in diameter and 3.3 mm thick. They come in a variety of capacities, including 10-lb and 25-lb models that are perfect for measuring loads similar to that of human fingers. All feature a non-repeatability of 0.1 percent, an operating temperature range of -51 deg C to 93 deg C, and a 17-4 PH stainless steel housing to handle a wide range of environmental conditions.

FUTEK high speed/resolution USB220 (left) and SENSIT Software FSH03189.

Finally, given the varying labs and test environments that robotic prosthetics are tested in, flexibility and ease of interface to lab computers is essential. Here, FUTEK's miniature button load cells interface with not only PLCs, but also FUTEK's USB 24-bit interface kits paired with their SENSIT Test and Measurement Software for live logging and graphing on a PC.

Source: FUTEK

Published June 2016

Rate this article

View our terms of use and privacy policy